Aviation

Additive technologies attract aircraft designers not only by their cost efficiency. They enable manufacturing of products with a large quantity of closed cavities, honeycomb structures and embedded cooling channels. Finally, additive technologies allows to topologically optimize the shape of the future product still at the stage of a model, thus considerably improving operational characteristics and reducing the weight of the ready product.

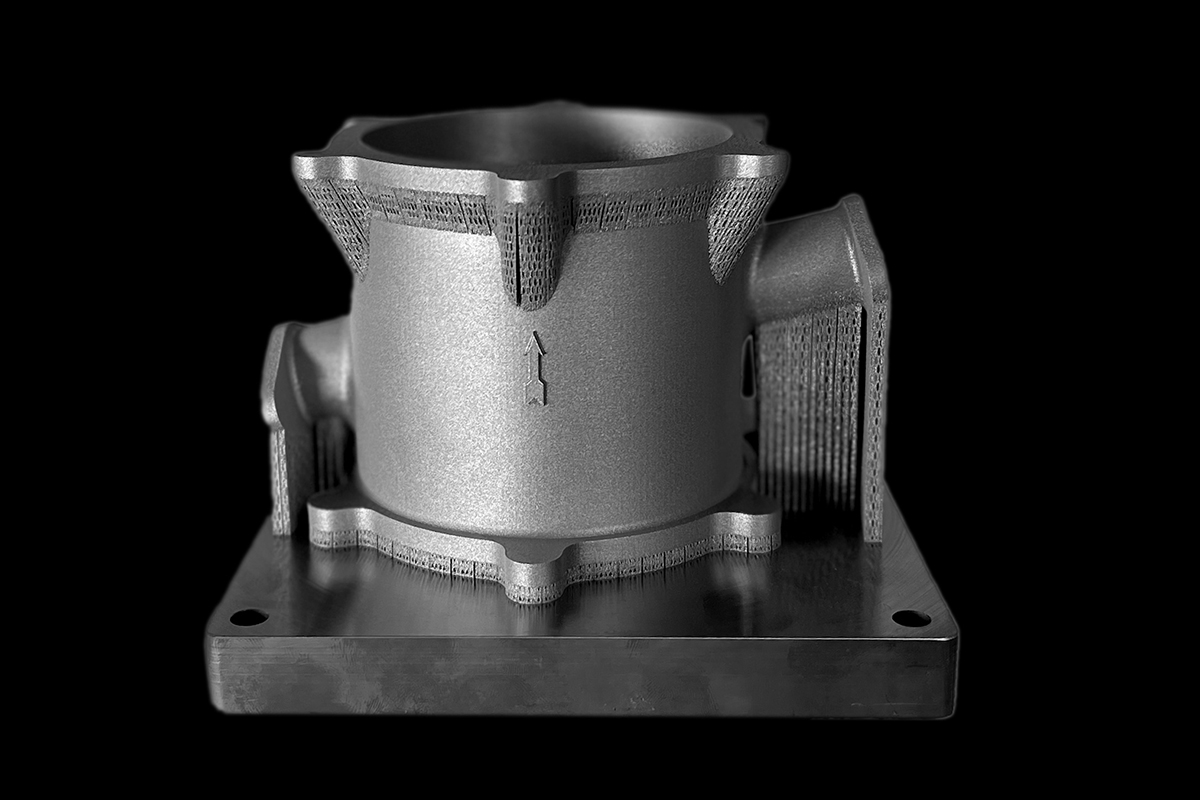

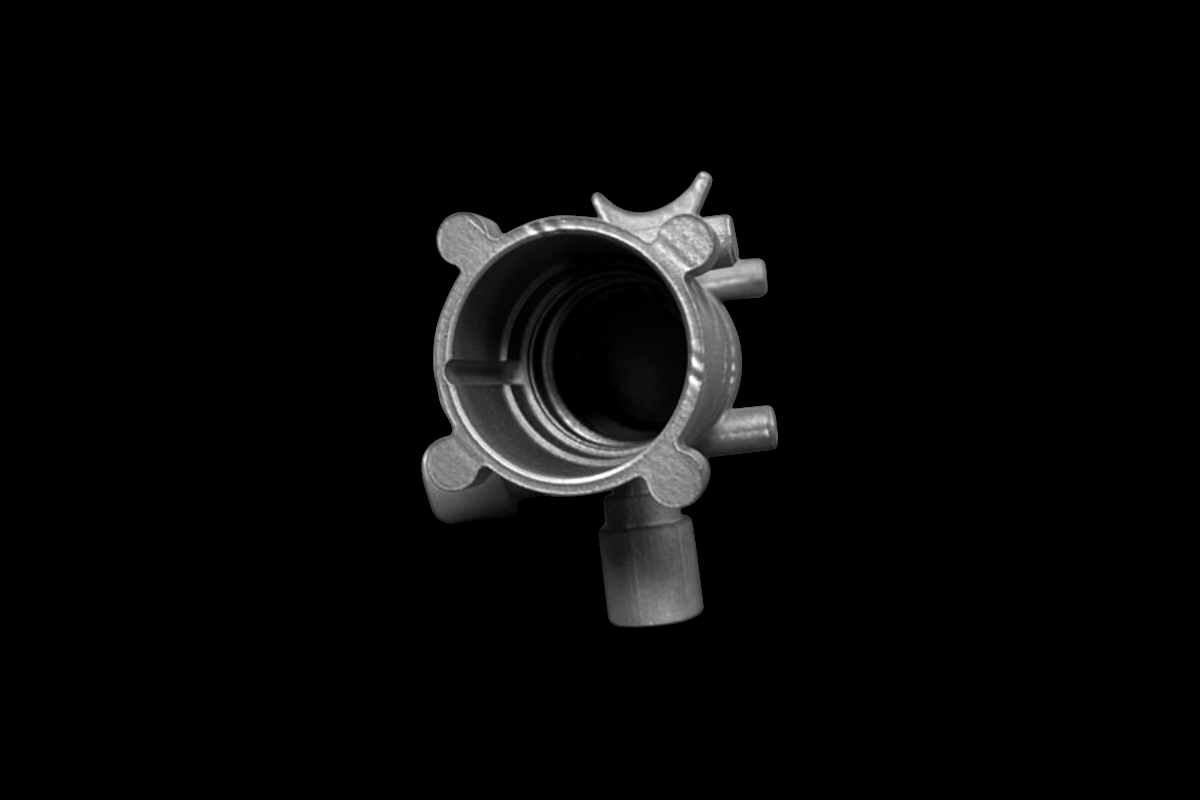

An example of topological optimization of a aircraft standard milled bracket

Replacement of a standard milled bracket with a similar made with Alpha-280N 3D printer after its topological optimization resulted in reduction of its initial weight from 154 g to 26 g with complete preservation of all its functional properties. For passenger airplanes, a lighter structure means saving of expensive fuel, which reduces not only direct costs of airlines, but also environmental damage.

Material: AlSi10Mg

Material: Ti6Al4V

Material: Ti6Al4V

Material: AlSi10Mg

Material: Inconel 718

Material: Inconel 718

Material: CoCrMo

Material: Ti6Al4V

Powder Bed Fusion

Powder Bed Fusion is an innovative technology for manufacturing geometrically complex products by application of the powder, layer after layer, and local melting of selected areas of each layer of the powders of various metal alloys to form a shape presented as a CAD model. As the source of energy, a high-power ytterbium fiber laser of continuous radiation is used. This process is successfully ousting out traditional manufacturing methods, as physical and mechanical properties of products manufactured with it, as well as their geometry, surpass those of analogs manufactured with traditional technologies

Read more3D printers and auxiliary equipment

3D printer Alfa-150D

A compact solution for ambitious and high-precision industrial and research issues

Read more

Vacuum powder removal units

Devices are intended for collection of unused metal non-reactive powder from the work area of the Alfa-150D and Alfa-280N 3D printers

Read more

Automated metal powder sieving units

Devices for sifting, mixing and homogenizing metal powder for reuse

Read moreContact us

If you have any questions about 3D printing, or you need support in finding the material and equipment to solve your technological problems, please complete the feedback form: our manager will contact you as soon as possible